Table of Contents

Working in different environments comes with a string of different needs. Calculating all of these into the processes is a crucial thing to do. Otherwise, you might not accomplish everything needed to complete the job. A good example of this is finding proper tools to help achieve the best possible results. Of course, it is necessary to understand all the particularities before you can be successful enough.

As you know, the industries come with different requirements. With that in mind, understanding the modus operandi for all of them is an absolute must. The modus operandi for different procedures is more than meets the eye. At first, it might look flawless and easy enough. But when you scratch the surface, you will see numerous elements make the big picture. It is more complex than we usually think.

When you look at all the most important trends of this day and age, regardless of industry, you see that automation is the most prevalent. Every company tries to automate processes to avoid wasting time and resources. But for it all to work, the machinery should be calibrated. Machines require parts such as ball screws and linear blocks to achieve that level.

Today, we would like to discuss these two in depth.

What are the Ball Screws?

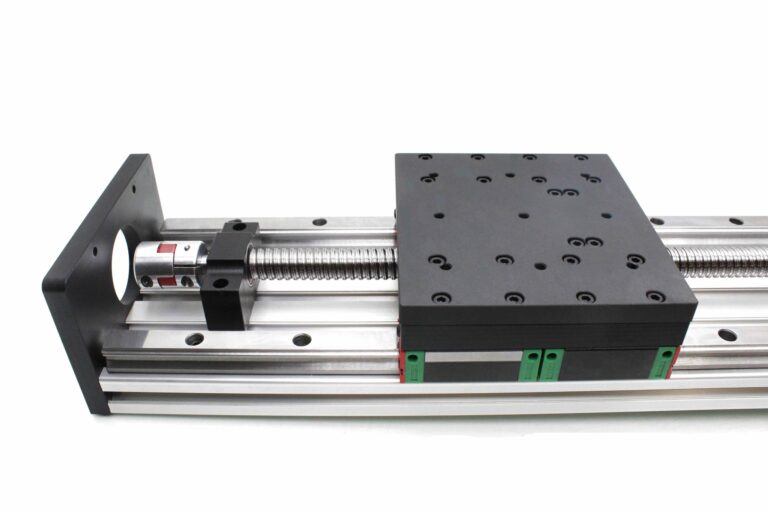

The first sort we want to discuss is ball screws. We are talking about linear actuators that consist of a nut that contains a rolling ball between the matching grooves. At the same time, a screw shaft is a part of that composition. Combining these two elements makes it possible to connect the two parts of a machine to work consistently. However, the primary function of these parts is better known as a conversion.

We are discussing the conversion between two parts, stationary and dynamic load. Of course, the conversion should be conducted with the utmost precision and accuracy. Not to mention that many repeats ensure the quality of the cooperation between all these parts. However, the most essential part of this composition is known as the rolling ball, or balls, that make the part work. Without them, much-needed flexibility could not be achieved.

Another major point why rolling balls are essential is that they help replace the sliding with rolling friction. We all know that having something, in this case, balls, helps the structure move much easier. Furthermore, the danger of something going wrong is not as common as it may have been when talking about sliding parts. You will see why people prefer to use ball screws over many of its alternatives for all these reasons. If you don’t know where to look for these, check a ball screw by Tuli.

The Main Components

This list is not that long regarding the main components of ball screws. Nevertheless, all the elements you will find on this list are essential for it to function properly. The first element we want to discuss is the screw shaft. We are talking about the part that makes it possible for the ball screw to provide the rotational force to the construction, ultimately providing the much-needed flexibility we discussed earlier.

Besides the shaft, ball bearings are another significant element. The steel balls are located in these parts, allowing them to navigate freely without interruption. Surely, there is a time when these can get clogged for whatever reason. But when they are completely free from all the problems that might occur, then it is no surprise why every expert will tell you that ball bearings are something these parts cannot work without.

The next element worth knowing is the importance of lubrication. When you think about it, this is the most significant one by far. The part would not work properly without having the proper lubrication. Over time, the oil spread around the device will dry up, and the need for applying a completely new layer will arise. Individuals who work on these machines should know how to conduct this process properly.

Linear Blocks: What You Should Know?

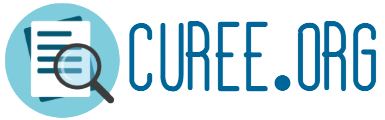

Linear blocks are another crucial part of modern machinery, especially when discussing the ones we can automate. The first thing everyone should understand is that they should be aware of three categories. We are talking about the linear wheel guide, followed by a ball and a cylindrical one. Surely, you will not use all of them at once. The worker would need to determine the right one for the case. It goes without saying that it should be the best quality linear blocks.

As you can presume, this requires expertise. The main aim of using linear blocks is to support the movement. These running smoothly is an absolute must. Otherwise, the functionality of the machinery wouldn’t be at the highest possible level. When it is not at the appropriate level, it can endanger different business functionality levels. If the production procedure starts declining, hoping to achieve success is not something you can do, right?

Choosing the Right Option

We’ve mentioned before that the worker at hand is the one who determines the type that will be used. Of course, this depends on a variety of elements. However, we would like to say that the company will set the rules in most cases and provide the conditions for the workers to be as efficient as possible. Besides that, it is important to point out that companies without needed experience must consult experts.

Thankfully, consulting experts in this field is not that challenging. They are available to everyone, especially today, with their websites open for every visitor. Without the needed experience, companies would inflict much more damage that can be easily avoided through proper consultation.

In Conclusion

Comprehending the importance of ball screws and linear blocks is essential for providing the right condition to your machinery. Of course, automation depends on this being the case. Here, you can check out the most relevant information regarding both these parts and how you can use them. We are certain you will find the information helpful.